Stories from the bike workshop: the flat tyre

Spring fever on two wheels - is there anything better? I don't think so. Unless the puncture witch strikes and you find yourself out in the sticks with no air in your tyres.

Spring has never been this early. At least not since 1896. On 20 March 2024, the sun was vertically above the equator at exactly six minutes past four in the morning Central European Time. This means that astronomical spring has begun in the northern hemisphere. Not a minute too soon for my taste. For many, this is the moment to kiss the bike awake from hibernation. And shortly afterwards, unfortunately, the first breakdown of the season often occurs.

Source: Patrick Bardelli

I get advice from a specialist

The most common breakdown? In addition to a slow puncture, which is often caused by an incorrectly screwed valve, I would guess tyre damage. A shard, nail or sharp stone punctures the tyre. In my case, that would be the tubeless tyre on my gravel or e-mountain bike. In such a case, good advice is expensive, so I get it from a specialist. More specifically, Elia Widmer from Hilite Bikes in Basel. The trained toolmaker is involved in the construction of their customised bikes and also works as a bike mechanic, taking care of minor and major ailments on racing bikes and the like

Source: Christian Walker

What to do in the event of a tubeless tyre puncture

These tyres have a special structure and ensure airtightness even without an additional inner tube. A sealant is filled into the tubeless system, which seals the hole from the inside in the event of a puncture. The advantage of tubeless tyres is, among other things, that their construction makes them less susceptible to punctures than tubular or folding tyres. However, they do require more maintenance. But more on this in a separate article.

As a rule, manufacturers of sealants state that their products can seal holes up to six millimetres in diameter. And they can do this while driving, in fractions of a second - without you having to do anything. Elia and I want to find out more about how and whether this works, so we maltreat the "G-One R" from Schwalbe, which I've been riding on for around nine months now. It breaks my heart a little to simply sacrifice this great tyre. But oh well.

Source: Christian Walker

The hole that Elia made in the tyre with the screwdriver is about six millimetres. However, the sealant still doesn't manage to close it. Of course, he had topped up the tyre with fresh sealant beforehand. Nevertheless, the tyre keeps losing the air that the Velomech pumps in.

If something like this happens off-road while riding and not intentionally in the workshop, you first have to find out where the damage has occurred on the tyre. To do this, Elia lays the bike on the ground, pumps air into the tyre and looks to see where the sealant is leaking. The particles in the milk, fibres etc., get stuck at the hole and form a plug there. If not, plan B comes into play.

Source: Christian Walker

How the plug gets into the bicycle tyre

The magic word is plug. These small "rubber sausages" are available from various manufacturers, in different sizes and colours. They are usually either black or brown - like the tyres. You also need a special tool to get the plugs into the hole and seal the tyre. The workshop at Hilite Bikes is of course fully equipped. Elia cuts a plug to the right size and uses it to close the hole in the Schwalbe G-One R tyre

Source: Christian Walker

Source: Christian Walker

Source: Christian Walker

I'm almost a little relieved, even the expert needs a few attempts to get the right size plug in the tyre and finally seal the hole. It is, as we say in Switzerland, a bit of a "knob". And I imagine how many curses I would send to heaven if I had to do this outside in winter with clammy hands. Not like today in the cosy workshop.

In the end, the plug in the tyre and the staged puncture are fixed. Elia refills the tyre with sealant and pumps it up again. That's it.

Source: Christian Walker

Products you need

Are you riding with tubeless tyres? Then it is advisable to always have the following materials and tools with you just in case:

- Plugs incl. tools

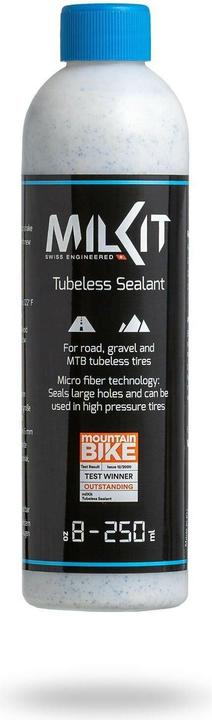

- Sealant milk

- CO₂ cartridge/hand pump

I have linked corresponding examples here. Of course, you can find similar products from other suppliers in our virtual Velowerkstatt. You will also need a pair of scissors, such as small nail scissors, to cut the plugs to size on the go.

There are also manufacturers, such as Milkit, who have developed a special tool set with scissors already built in. However, these are quite small and unwieldy. What's more, the item has a hefty price tag.

More stories from the bike workshop to follow. The topics: new tubeless tyres for gravel bikes, chain maintenance and no more squeaky brakes.

Header image: Christian WalkerFrom radio journalist to product tester and storyteller, jogger to gravel bike novice and fitness enthusiast with barbells and dumbbells. I'm excited to see where the journey'll take me next.